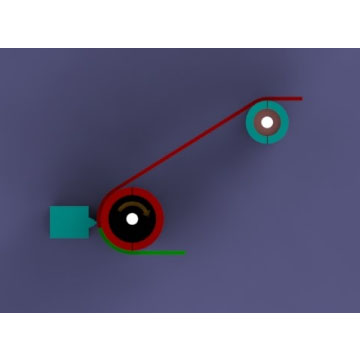

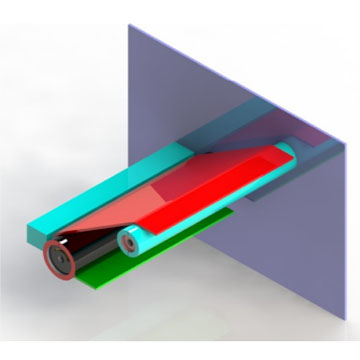

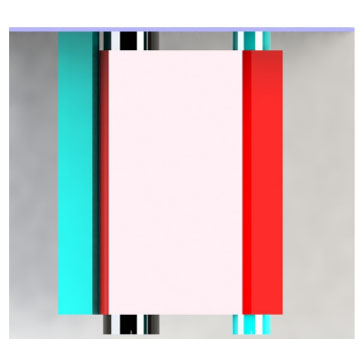

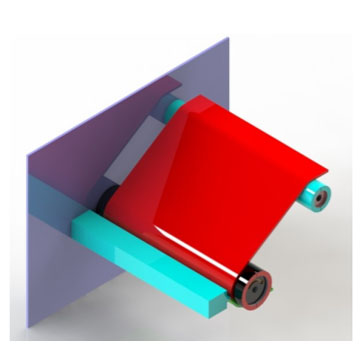

In the Slot Die process, the coating is pressed out by gravity or under weight through a slot and onto the substrate. In the event that the coating is 100% solids, the process is termed "Extrusion" and for this situation, the line velocity is regularly much speedier than the rate of the extrusion. This empowers coatings to be significantly more slender than the width of the slot. Slot Die Coating is a repeatable, solid coating strategy that keeps on gaining support in a mixed bag of coating.

Advantages

- Able to Coat Organic or Inorganic Liquids on flexible or rigid substrates

- Excellent coating uniformity (typically ±3% or better)

- Capable of coating a wide range of process materials: high and low viscosity fluids

- Deposit a wide range of thicknesses

- High efficiency / high material utilization: typically 96% process material utilization

- Technology proven scalable from small R&D to large panel, high volume/mass production

- Highly reliable and robust process

- High throughput (low TACT) processing

Related Images