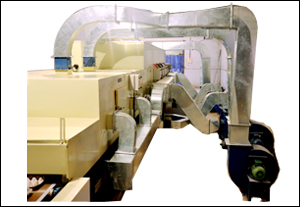

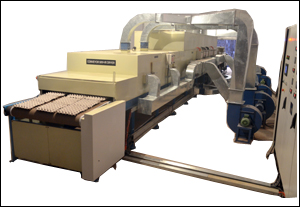

The principles of microwave heating as applied to industrial processing are outlined and the basic design of applicators for material processing is described. Industrial applications range from food tempering to rubber vulcanisation and from vacuum drying to sintering of ceramics. Established applications to date are summarised.

Microwave heating is a process within a family of electroheat techniques, such as induction, radio frequency, direct resistance or infra-red heating, all of which utilise specific parts of the electromagnetic spectrum. These processes supplement, and in specific cases totally replace, conventional heating or drying systems used in industry. This is because some conventional systems are very bulky, not easy to operate, can pollute the environment due to harmful omissions and above all can be very inefficient.

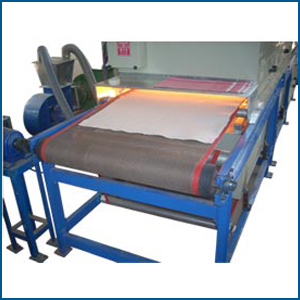

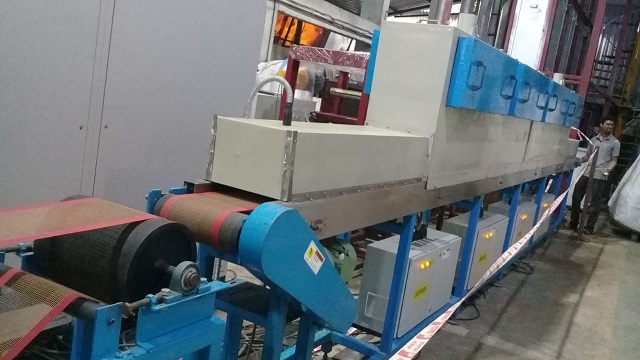

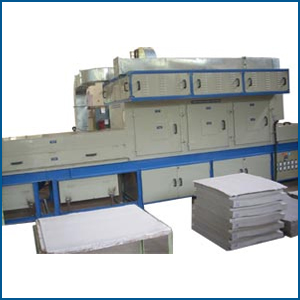

The major advantages of using microwaves for industrial processing are rapid heat transfer, volumetric and selective heating, compactness of equipment, speed of switching on and off and pollution-free environment as there are no products of combustion. Microwave leakage can certainly be kept well below government recommended levels.