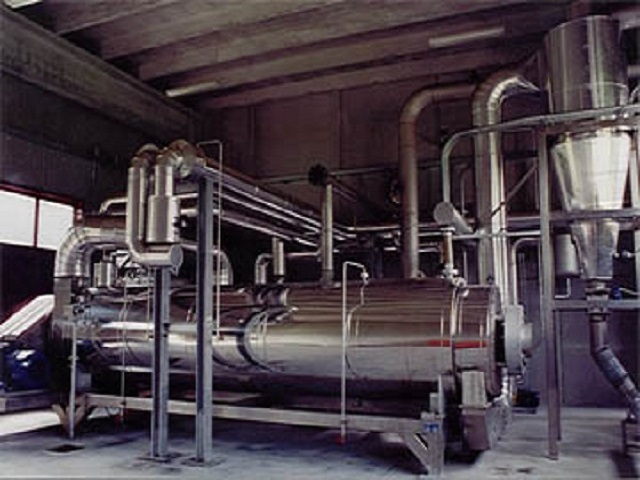

ETP Sludge is the industrial waste generated during the production method of the Industrial sewage processing. As sludge has a number of drawbacks, including a high moisture content, a high viscosity, a high capacity to hold water, and a low calorific value. Getting industrial utilization is hard. KERONE conducted a number of technical studies on the state of the sludge treatment industry today and the features of sludge in different geographical areas. With a drying product moisture reduction of less than twenty-five percent, KERONE Concentrating developed a new generation of sludge rotary drum drying systems that ultimately met the quality requirements for sludge landfills and further incineration process conditions. Equipment technology is being sufficiently developed to have a reliable operating capacity and be incredibly easy to use and maintain.

KERONE carried out several technical studies on the characteristics of sludge in various regions and the current status of the sludge treatment business. KERONE Concentrating created a new generation of sludge rotary drum drying systems that, in the end, satisfied the quality standards for sludge landfills and subsequent incineration process circumstances with a drying product moisture reduction of less than 25 percent. Technology for equipment is progressing to the point where it may operate with great reliability and be very simple to use and maintain.

For sludge producers with different capacities, Kerone has designed and produced sludge drying systems that work with them. Plants can install drying systems in remote locations or directly load them by installing them under the filter press. As the sludge is heated to a temperature below zero, almost all of its water—including capillary, cell, and surface water—evaporates. If at all possible, a mutual power and heat producing system must provide the heat supply. Many of the drying heat particles are recirculated from the exhaust.